Pump Tracks Tomorrow Trends Shaping the Ride

Pump tracks have come a long way from simple dirt loops. Riders everywhere chase that smooth flow, building speed without a single pedal stroke. But what’s next? This post dives into emerging shifts in pump track design and use, drawing from real-world changes in materials, community spaces, and tech. For more on the basics, contact us to see how these tracks started.

The Evolution of Pump Tracks

Back in the early days, riders carved paths from soil. These worked fine until rain hit, turning everything into mud. Maintenance ate up hours. Then came harder surfaces like asphalt and concrete. Solid, sure, but pricey and fixed in place. Now, things shift toward smarter builds.

Modular setups lead the charge. They snap together like building blocks, letting users tweak layouts on the fly. A park in British Columbia added one to an RV spot, drawing families for quick sessions amid camping trips. No big digs needed—just assemble and ride.

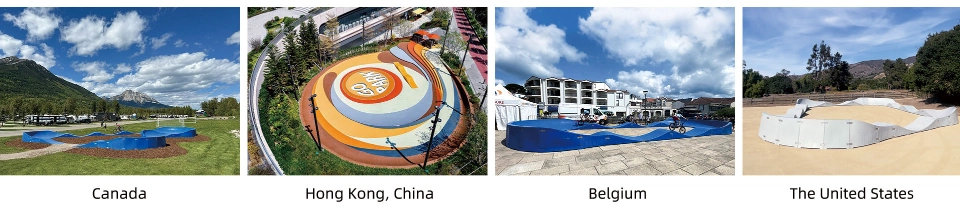

This change ties into broader pump track trends. Cities squeeze them into tight spots, from urban plazas to schoolyards. In Hong Kong, a massive outdoor hub included one alongside football fields and paths, pulling in crowds for casual fun. Riders of all ages hit the rollers, boosting skills without the hassle of traditional parks.

Materials Driving the Future

What holds these tracks together matters more than ever. Early versions used wood or dirt, but weather wrecked them fast. Rain made surfaces slick; sun warped edges. Today’s focus lands on tough plastics that shrug off elements.

Think injection-molded pieces. They resist fading, cracking, and slips, even in scorching heat or freezes. Tests show they handle extremes from -20°C to 50°C, keeping grip steady. One setup in Saudi Arabia parks endured 50°C days, logging over 300 riders weekly without fade.

This push for durable pump track materials cuts costs long-term. No constant fixes mean more ride time. Plus, colors stay bright, adding pop to public areas. A Denver pop-up event moved a full track twice daily, fitting everything in one truck. Quick setup drew 300 riders over three days, proving portability wins in busy spots.

But it’s not just toughness. These materials open doors for custom fits. Backyards in California now host compact versions, where kids build balance and burn energy. Grandparents watch as eight-year-olds loop endlessly, turning home spaces into mini adventure zones.

Tech Integration in Pump Tracks

Riders want more than bumps and turns. Apps track laps now, logging speeds and tricks. Sensors in some tracks measure flow, helping beginners tweak their pump.

This blends with future of pump tracks by making sessions smarter. Coaches use data to spot weak spots, like poor weight shifts over rollers. In competitive scenes, this edges out wins.

Yet, basics stay key. Tracks still teach core moves—push-pull over humps for momentum. Tech just adds layers, like virtual challenges overlaid on real paths.

Community and Accessibility Gains

Pump tracks pull people together. Unlike solo rides, these loops spark group vibes. Skateboarders mix with scooter kids; BMX pros share tips with newbies.

In Belgium, a skatepark owner rented modular units for events. He hauled one to France for a dusk setup, ready by morning. Events like this spread the word, turning spots into social hubs.

This ties into bigger benefits of pump tracks. Health perks shine—kids ditch screens for active play, building coordination. Communities see less idle time, more bonds. One Canadian resort added a track, mixing it with golf and water sports for all-day draws.

Expansion matters too. Start small, add modules as funds roll in. A landscape project in the Middle East grew from basic loops to complex flows, fitting garden designs without heavy permits.

Sustainability in Pump Track Builds

Green thinking shapes choices. Recycled plastics cut waste, while modular designs mean less land disruption. Tracks move if needed, avoiding permanent scars.

This aligns with pump track for communities. Parks aim for low-impact fun. In rainy zones, weatherproof surfaces mean year-round use, no erosion worries. Warranties stretch to five years, backing long hauls.

Numbers back it: Lifespans hit 8-10 years with light care. Compare that to dirt tracks needing weekly tweaks after storms.

Business Side: Growth and Opportunities

For suppliers, the game changes fast. Dealers spot demand in pop-ups and rentals. An American agent in Denver used quick builds to test markets, sparking sales queries from parents.

This boosts pump track business trends. Global reach expands, with shipments hitting Australia in 20-25 days or Europe in 55-60. Flexible payments—50% down, rest on ship—ease entry.

Cases show wins: A Belgian pro diversified his gear rentals with tracks, adding stunt shows. In residential spots, doctors install them for family fun, turning backyards into skill builders.

Table below highlights key shifts:

| Aspect | Past | Future Direction |

| Materials | Dirt, Wood | Weatherproof Plastics |

| Setup | Fixed Builds | Modular, Quick Assembly |

| Use | Bike-Only | Multi-Wheel Inclusive |

| Maintenance | High, Frequent | Low, Durable |

These moves keep tracks fresh. Riders get endless configs, from simple ovals to wild mazes.

Innovation in Layouts and Customization

Designs evolve beyond basics. Six core modules mix for varied paths, with extras on request. A Hong Kong park blended one with pickleball courts, creating all-in-one spots.

This flexibility suits budgets. Phase in expansions—start with essentials, grow as riders demand more. No full overhauls; just bolt on pieces.

Introducing ULTRAPUMPTRACK as a Pump Tracks Supplier

As a key player in this space, ULTRAPUMPTRACK delivers modular systems built for real-world demands. From initial dirt and asphalt roots in 2012, the company shifted to plastic modules by 2015. Now in its third generation, these tracks offer fast assembly, custom colors for $1500-$2000 extra, and no-permit ease in many spots. Head to our site for details on how they fit diverse settings, like RV parks or urban events. With a focus on durability and fun, ULTRAPUMPTRACK supports riders worldwide through reliable builds and five-year warranties.

Conclusion

Pump tracks head toward inclusive, tough, and smart futures. They blend community pulls with material wins, ensuring rides stay thrilling. As spaces adapt, these tracks promise more access and less hassle, keeping wheels turning for years.

FAQs

What trends define the future of pump tracks?

Shifts lean toward modular designs and weatherproof materials. These allow quick changes and year-round use, as seen in global installs from deserts to coasts.

How do modular pump tracks benefit beginners?

They offer safe spaces to learn pumping basics. Kids build skills on the anti-slip surfaces, with low slips and easy expansions for growing challenges.

Are pump tracks sustainable for long-term use?

Yes, with lifespans of 8-10 years and minimal upkeep. Plastics resist weather, cutting erosion compared to dirt versions.

What makes pump tracks ideal for communities?

They unite riders across wheels—bikes, skates, scooters. Low costs and no big permits mean fast setups in parks or backyards.