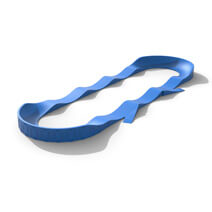

| Layout name |

Prime time |

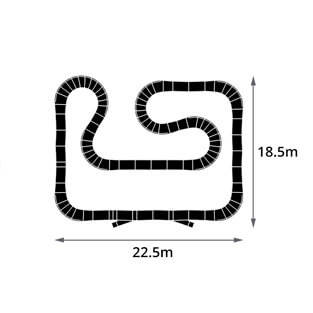

| Length of the track |

104m |

| Layout area |

22.5m x18.5m |

| Number of modules |

102 |

| Net weight |

4793kg |

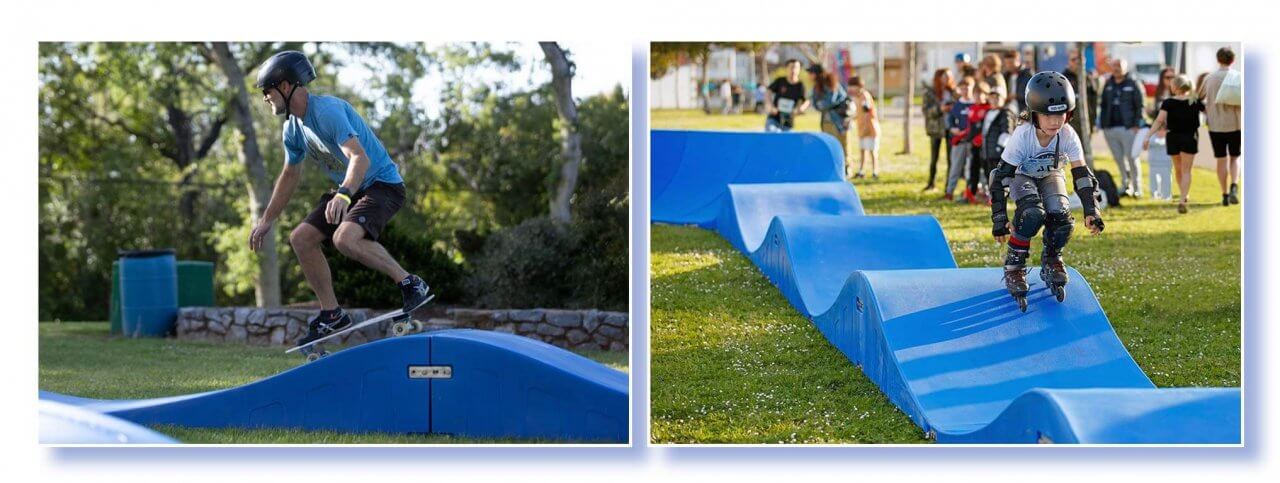

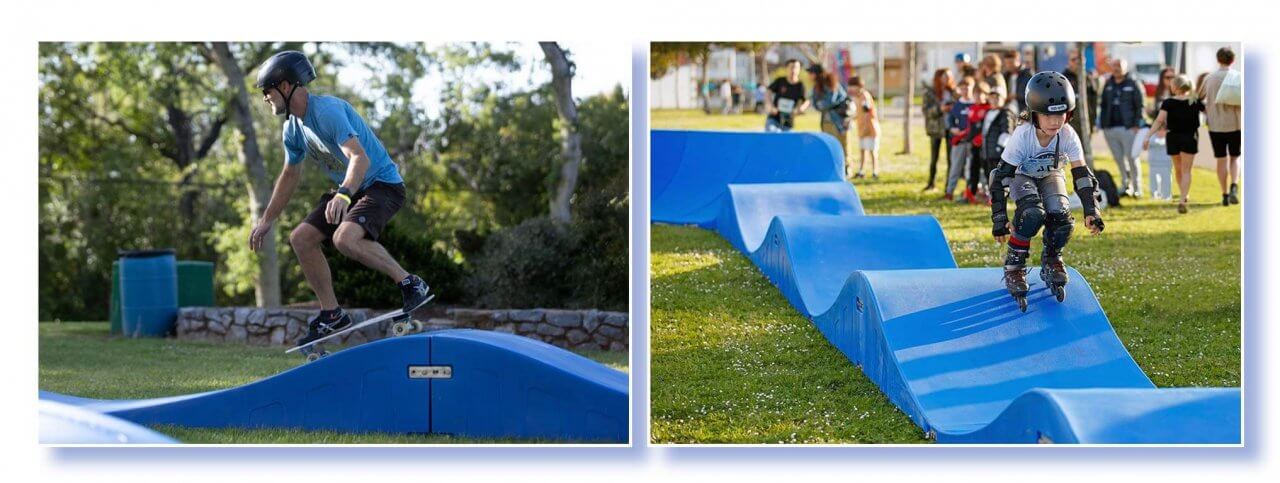

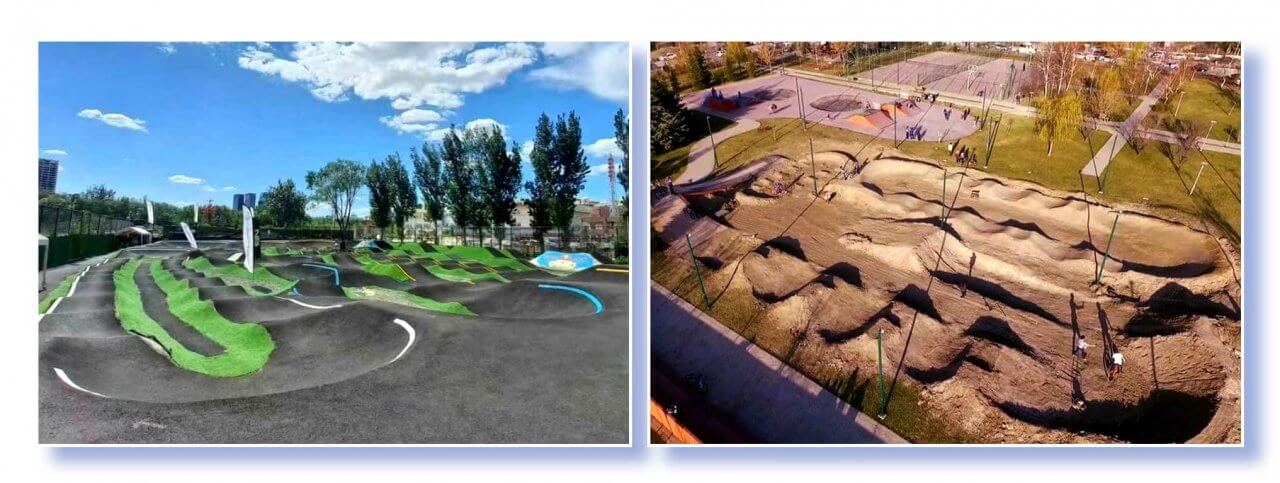

The modular pump track, designed for wheeled sports enthusiasts, offers a thrilling experience that doesn’t rely on pedaling or pushing. Instead, it’s all about mastering the art of “pumping” to maintain momentum and glide seamlessly through the track.

Pump tracks serve as the foundation for various action sports, providing a safe space for kids to learn and develop their skills on bikes, skateboards, and scooters. Unlike traditional skateparks, modular pump tracks are more accessible, encouraging greater participation in sports. In my opinion, pump tracks should be as common as Fitness and sports facilities in every town.

Modular pump tracks are rapidly gaining popularity as innovative play park amenities, finding their place in more and more public spaces. Their appeal lies in the dynamic and engaging experiences they offer to people of all ages.

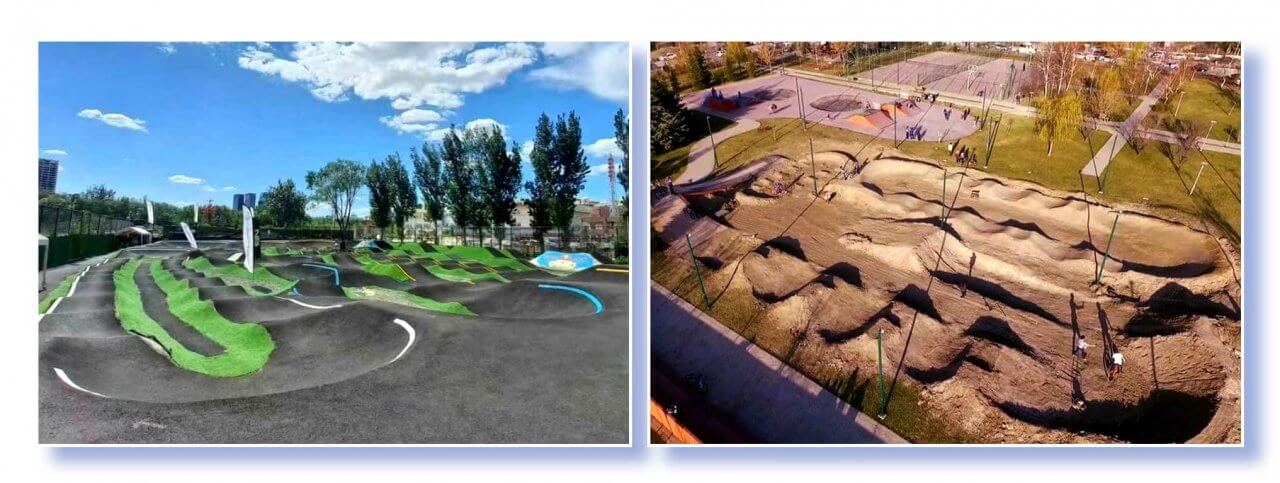

There are various material options for pump tracks, including cement, asphalt, earth, wood, steel-plastic, and plastic. However, each material has its limitations. Soil and wood tracks are unusable in rainy conditions, while cement and asphalt tracks cannot be easily moved or changed. Steel-plastic assembly can be cumbersome.

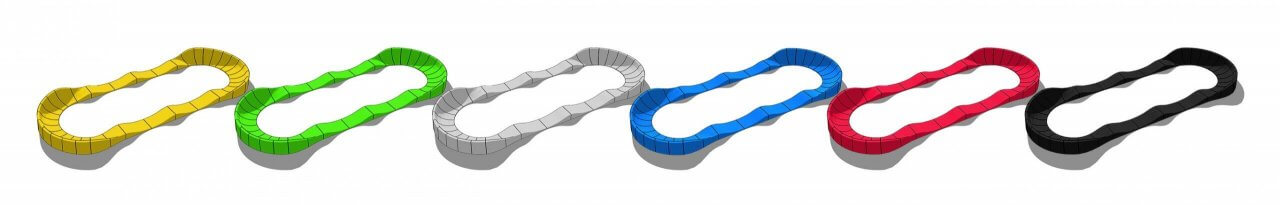

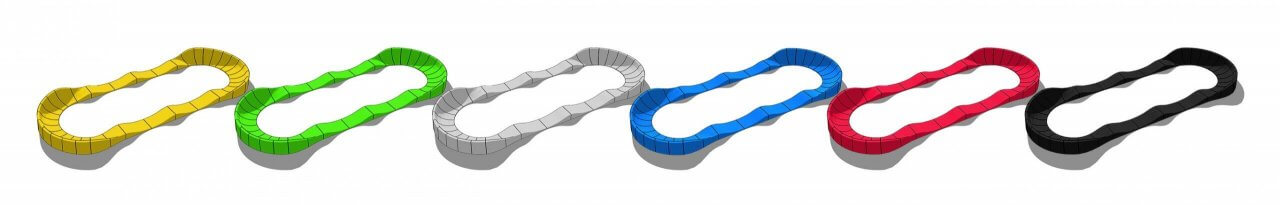

On the other hand, Our “pump track” stands out as it is cast using injection molding. This environmentally friendly track is rainproof, antifreeze, and lightfast, making it suitable for outdoor use. It assembles quickly, offers a variety of configurations, and provides the option to choose from a range of vibrant colors.

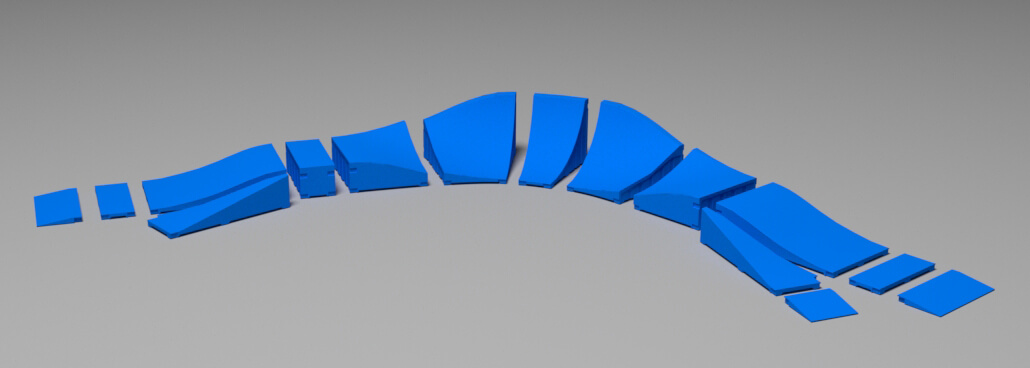

Its anti-skid design guarantees stability during glides. With high precision, excellent consistency, and fast delivery, the injection molding process ensures the utmost quality. The “pump track” material surpasses others in terms of temperature resistance, wetness endurance, and slip resistance.

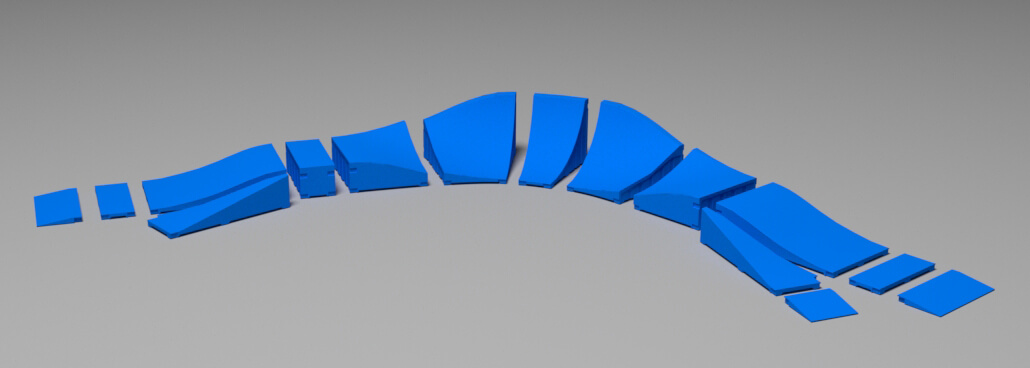

The “pump track” has applied for utility model and appearance patents. Its sixteen basic modules can be combined to create a wide array of running tracks. We are also capable of developing additional modules according to customer requirements.

Assembly is quick and easy, thanks to the simple connection design.Basic tools are sufficient to assemble the track without complications.

One of the significant advantages of a modular system is its expandability.The pump track layout can be modified at any time, and the track’s size can be increased as budget allows. This keeps the facility fresh, exciting, and adaptable while allowing clients to manage costs by implementing a phased approach.

Our Composite Pumptracks have the advantage of often not requiring Planning Permission for installation. This makes projects more feasible and reduces the time from concept to completion.